Lipophilic active substances, such as fat-soluble vitamins (vitamin A, vitamin D, vitamin E), carotenoids (astaxanthin, β-carotene, lycopene), polyphenols (curcumin, quercetin, resveratrol), polyunsaturated fatty acids (ω-3), essential oils, etc., are widely used because they not only have physiological functions such as antioxidant, anti-inflammatory, and antibacterial, but also can protect human health and reduce the risk of cardiovascular disease, cancer, and neurodegenerative diseases. Studies have found that lipophilic active substances have low water solubility and are easily oxidized or denatured by environmental factors such as light, temperature, and oxygen during processing and storage. After oral ingestion, they are restricted by the gastrointestinal environment such as gastric acid and protease and are difficult to be absorbed and digested by the small intestine, showing extremely low bioavailability. Therefore, the design and development of lipophilic active substance delivery carriers has become a research hotspot in recent years. Nanocarriers are tiny in size and can easily penetrate the target cells through the cell wall. They can also increase the surface-to-volume ratio and enhance the adhesion of the small intestine, which makes them an effective method and approach to improve the stability of lipophilic active substances, regulate the release time and absorption site, and achieve controlled and targeted release. Currently, polymers used as nanocarriers are divided into natural polymers and synthetic polymers. Natural polymers such as proteins and polysaccharides have the advantages of lower cost, biocompatibility, biodegradability and non-toxicity, and show better adhesion and targeting, making them a good choice to replace synthetic polymers.

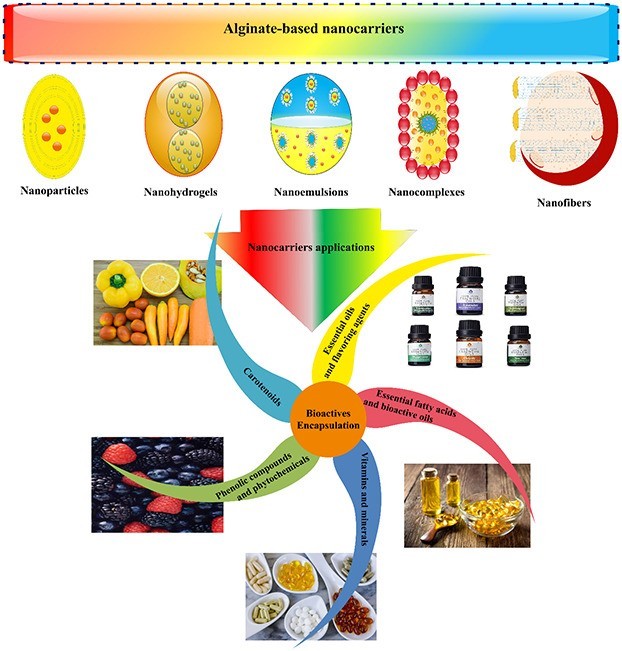

Figure 1. Alginate-based nanocarriers for the delivery and controlled-release of bioactive compounds. (Karim A, et al.; 2022)

Figure 1. Alginate-based nanocarriers for the delivery and controlled-release of bioactive compounds. (Karim A, et al.; 2022)

Alginate, as an unbranched anionic polysaccharide, has biological properties such as mucosal adhesion and antioxidant activity. It can provide a barrier effect for lipophilic active substances by chelating pro-oxidative metal ions, and alginate can also use ion induction to form gels with different characteristics. The gels have conditions are mild and suitable for loading sensitive and volatile lipophilic active substances. In addition, the large number of carboxyl groups in alginate makes it pH responsive, effectively improving the bioavailability of lipophilic active substances, and functional groups can be introduced into the carboxyl groups to give it additional functions such as thermosensitivity or magnetism. Similarly, alginate, which has excellent properties, can be easily cross-linked with other materials to produce alginate nanocarriers with various properties, such as nanoemulsions, nanoparticles, nanogels, and nanofibers, which makes alginate an ideal raw material for delivering lipophilic active substances.

Alginate is usually extracted from brown algae such as Macrocystis, Laminaria japonica and Nodularascus, and can also be produced by microbial fermentation of special bacteria. It is a linear copolymer composed of β-D-mannuronic acid (M block) and α-L-guluronic acid (G block) units connected by 1→4 glycosidic bonds. According to the sequence of the blocks, it can be divided into homopolymer (GG block or MM block) and heteropolymer (GM block) structures. The different proportions of M and G blocks in alginate determine the different molecular structures of alginate, which in turn affect its physical properties. Among them, the G block can provide rigidity to the polymer structure and show higher mechanical strength, and the M block can provide flexibility to the chain and give the gel a smaller pore size, which can reduce the permeability of lipophilic bioactive substances. Molecular weight is also a related factor affecting the physical properties of alginate. Changes in the molecular weight of alginate will directly affect the solution viscosity and the mechanical strength of the hydrogel, thereby affecting the protective effect of the nano-delivery carrier on lipophilic active substances. Alginate contains many free hydroxyl and carboxyl groups that can be modified and derived. Hydrophilic alginate can be chemically modified into amphiphilic or hydrophobic molecules, thus giving alginate new functional properties that are more conducive to stabilizing lipophilic active substances, making the nano-delivery system safer and more environmentally friendly. It can be seen that the G/M block ratio, molecular weight, free carboxyl and hydroxyl groups are the key factors affecting the properties of alginate nano-carriers. Reasonable design and modification of alginate provides more possibilities for the nano-delivery system of lipophilic active substances.

As one of the ideal carriers for lipophilic active substances, alginate-based nanocarriers can improve the stability of lipophilic active substances under the influence of factors such as light, temperature, and oxygen, provide a solid barrier for them to pass through the highly acidic and enzymatic gastric juice, and promote the efficient utilization of lipophilic active substances.

Nanoemulsions are dynamically stable colloidal dispersions formed by two immiscible liquids under the action of surfactants. According to the different relative distributions of the oil phase and the water phase in space, nanoemulsions are mainly divided into oil-in-water (O/W) type and water-in-oil (W/O) type. On the one hand, nanoemulsions can use the oil phase as a dissolution medium to improve the solubility of lipophilic active substances in the body. On the other hand, nanoemulsions have kinetic stability, and their small droplets can penetrate into the mucus layer of the small intestinal epithelial cells, thereby approaching the absorption site and increasing the residence time. In addition, small droplets with a large surface area can promote faster release and absorption of lipophilic active substances. However, since nanoemulsions are thermodynamically unstable and prone to phase separation over time under gravity, they often require stabilizers to improve storage stability. Alginate can improve emulsion stability by generating steric hindrance, increasing the viscosity of the continuous phase and the negative charge on the surface of the system, and is considered an excellent emulsion stabilizer.

Alginate nanoparticles generally have a particle size between 10 and 1000 nm and come in three different forms: nanoaggregates, nanocapsules and nanospheres. Compared to larger alginate particles, alginate nanoparticles have higher mechanical strength and specific surface area, and can form strong electrostatic and hydrophobic interactions with lipophilic drugs to achieve slower release. Alginate nanoparticles can be constructed in various ways, of which emulsification coupled with external or internal gelation of alginate emulsion droplets has been widely used. The emulsification coupled external gelation method usually involves adding alginate solution to the oil phase to form a w/o emulsion and then adding CaCl2 to gel it. The emulsification-coupled internal gel method refers to emulsifying an alginate solution containing insoluble calcium salts in the oil phase into a w/o emulsion, and then adding an oil-soluble acid to lower the pH to release Ca2+ from the insoluble calcium salts, thereby inducing the alginate nanoparticles to gel internally.

Nanogels are nanoscale hydrogels with 3D adjustable porous structures. In addition to the potential advantages of nanoscale preparations, they also have high hydration, shrinkage and swelling, high encapsulation rate and controlled release potential. Alginate nanogels have the physical and chemical properties of both nanogels and natural polymers. First, they have high water content, small particle size, and can use a unique three-dimensional network structure to encapsulate lipophilic active substances inside, solving the problem of degradation of active substances during storage. Second, alginate nanogels are stable under low pH conditions. Therefore, alginate nanogels are ideal carriers for oral delivery of unstable lipophilic active substances in the gastric environment.

Nanofibers are a new type of nanomaterial with the advantages of characteristic surface area to mass ratio, controlled surface morphology and porous mesh structure. Currently, the technologies used to manufacture polymer nanofibers include stretching, template synthesis, phase separation, self-assembly and electrospinning technology. Among them, electrospinning technology is a common method for alginate nanofibers because of its simple process, economic efficiency, and applicability to industrial production. Alginate nanofibers have unique flexibility, high porosity, and high aspect ratio, and are therefore widely used in food packaging. In addition, as a natural polymer, alginate also has excellent biocompatibility, biodegradability, non-toxicity, and good property retention, which make alginate a good raw material for preparing nanofibers to deliver lipophilic substances.

References

1. Download the template.

2. Enter product information on the template (maximum number of products: 200).

3. Load the file using selector below.

1. Download the template.

2. Enter product information on the template (maximum number of products: 200).

3. Load the file using selector below.