Low dispersion index polymers are a class of polymer compounds with low molecular weight dispersion. Typically, the structure of these polymers is designed to reduce their dispersion in solution, thereby increasing their stability and controllability. This type of polymer has important applications in the field of drug delivery, mainly because of their ability to efficiently carry and release drug molecules, improving the bioavailability and therapeutic effect of the drug.

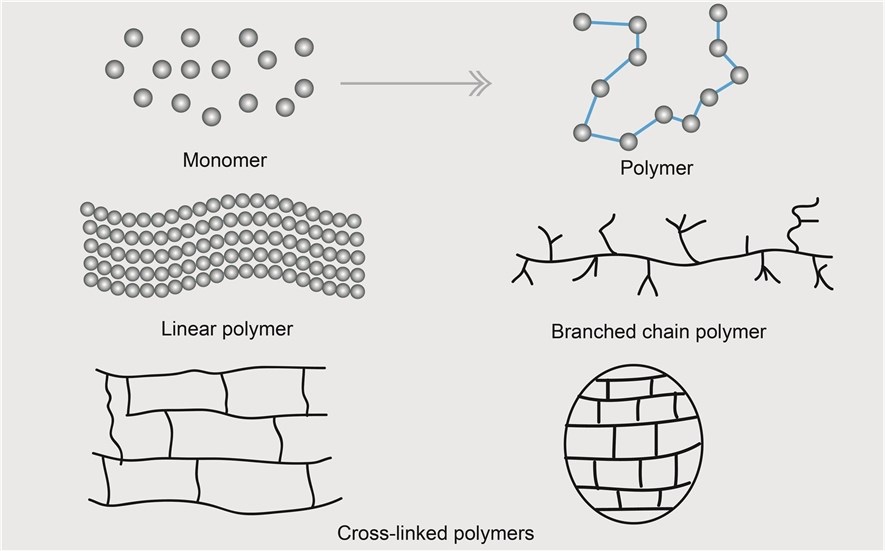

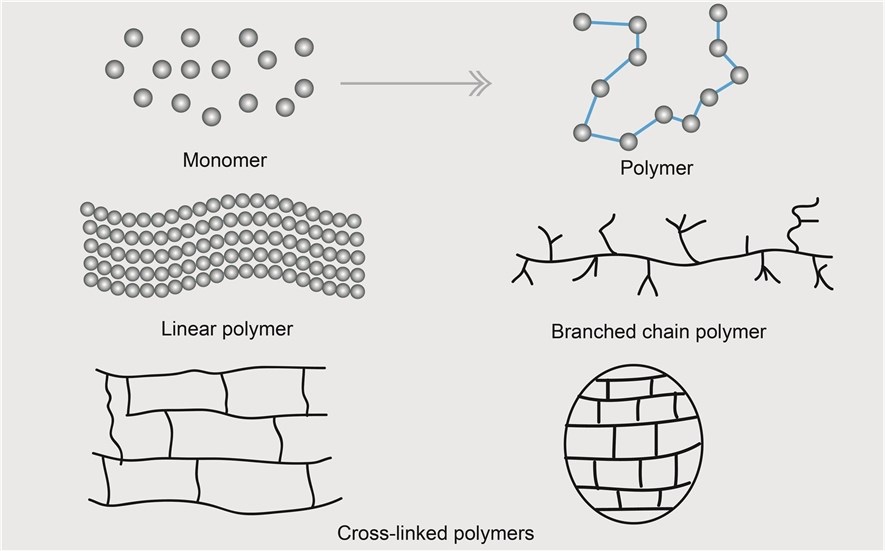

Figure 1. Low PDI Polymers structure diagram.

Figure 1. Low PDI Polymers structure diagram.

In the field of drug delivery, low dispersion index polymers are often used as drug carriers. These polymers form stable nanoparticles or microparticles in which drug molecules are encapsulated. The design of this kind of drug carrier can help overcome some of the limitations of traditional drugs, such as issues with biological stability, water solubility, and drug distribution in the body.

To this end, CD Bioparticles provides low PDI polymers for drug delivery system to help solve the following challenges.

The challenges you might meet:

- Low water solubility of drugs limits their absorption and distribution in the body, thereby limiting their bioavailability.

- Drug molecules are susceptible to environmental factors such as light, oxygen and humidity, which reduces the stability and storage life of the drug.

- Drugs need to be delivered in a targeted manner to reduce the adverse effects on normal tissues and at the same time increase the concentration of the drug at the lesion site.

- The drug cannot be released in a controlled manner, leading to problems with doses that are too high or too low.

- It is necessary to realize the joint delivery of multiple drugs to improve the therapeutic effect while reducing the inconvenience for patients to take multiple drugs separately.

Low PDI polymers key features:

Low PDI polymers key benefits:

- PDI is an index that measures the width and narrowness of polymer molecular weight distribution. Low PDI means that the molecular weight distribution is more concentrated, narrow and symmetrical. This narrow distribution helps ensure the similarity of monomer units in the polymer, improving product consistency and quality.

- Polymers with low PDI generally have more precise and controllable physical and chemical properties. This makes it easier to control the structure of the polymer during synthesis, helping to achieve the performance requirements of specific application areas.

- Polymers with higher and lower PDI generally exhibit higher reaction efficiencies in synthesis reactions. Due to the narrower molecular weight distribution, the structure of the polymer is more uniform. This helps form stable drug carriers and achieve controlled drug release.

- The narrower the molecular weight distribution of the polymer, the more regular its structure, which helps to reduce the toxicity and immunogenicity of the polymer.

- Polymers with low PDI can provide more precise and controllable drug loading, helping to ensure uniform distribution of drugs in the delivery vehicle and maximizing the efficacy of the drug.

- Polymers with low PDI can better control the shape and surface properties of the carrier, thereby achieving targeted delivery of drugs. This helps to increase the concentration of drugs in the diseased area and reduce the impact on normal tissue.

- Drug delivery systems need to remain stable in the in vivo environment to ensure effective drug delivery. Polymers with low PDI help improve the stability of drug carriers and reduce fluctuations during breakdown and release in the body.

Low PDI polymers application candidates:

- Low-PDI polymers can be used to construct nano-drug carriers, form stable nanoparticles, improve the water solubility of drugs, enhance stability, and achieve precise drug release, and are suitable for various drug delivery systems.

- By using low-PDI polymers, microspheres or nanocapsules can be prepared. These carriers can be used to encapsulate and protect drugs while providing the ability to control release to meet specific therapeutic needs.

- Polymers with low PDI can help construct targeted delivery systems. By adjusting the structure and surface properties of the polymer, targeted delivery of drugs can be achieved, increasing the concentration of drugs in diseased areas and reducing adverse effects on normal tissues.

- Polymers with low PDI have advantages in the preparation of hydrogels and nanogels, which can be used in applications such as drug delivery, wound healing, and tissue engineering, providing good biocompatibility and drug release properties.

- Low-PDI polymers can form stable micelle structures that can be used to encapsulate hydrophobic drug molecules and provide an effective delivery method to improve drug solubility and bioavailability.

- Low-PDI polymers help build long-lasting release systems. By adjusting the molecular weight and structure of the polymer, they can achieve sustained release of drugs in the body, reduce the frequency of medication, and improve patient convenience and compliance.

Figure 1. Low PDI Polymers structure diagram.

Figure 1. Low PDI Polymers structure diagram.