CD Bioparticles offers a wide range of high-quality biopolymers and synthetic polymers that have been validated for drug delivery. Using these nanocarrier systems, targeted drug molecules can be delivered to fixed targets efficiently and reliably and released in a controlled manner.

Find the right Biopolymers & Synthetic Polymers from CD Bioparticles

Low PDI Polymers

Low dispersion index polymers represent a category of polymer compounds that exhibit low molecular weight dispersion. The structural design of these polymers functions to minimize their dispersion in solution which results in enhanced stability and controllability. These polymers are essential in drug delivery systems since they transport and release drug molecules effectively which enhances both the bioavailability and therapeutic outcomes.

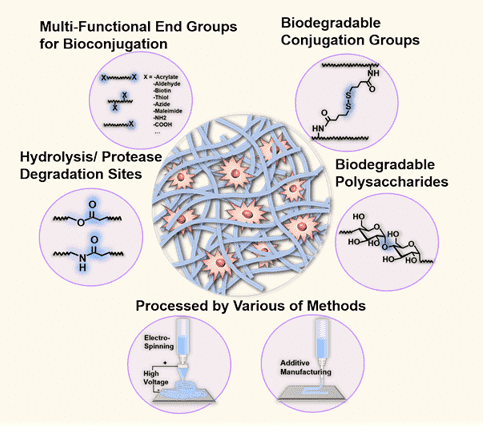

Biodegradable Polymers

Drug delivery systems now more interested in biodegradable polymers as their essential material choice. Controlled degradation allows these systems to deliver drugs effectively by maintaining sustained release while targeting specific areas and minimizing toxic side effects. PLA and PLGA serve as synthetic polymers with adjustable degradation and biocompatibility that make them ideal for long-acting analgesic applications and localized tumor chemotherapy among other uses.

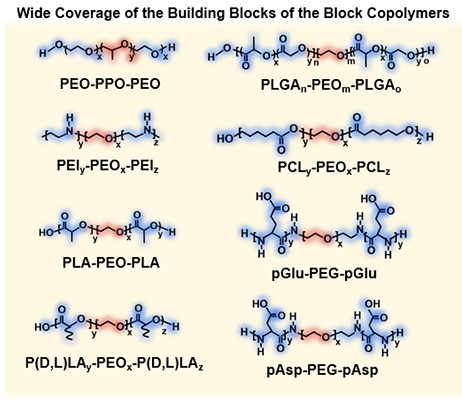

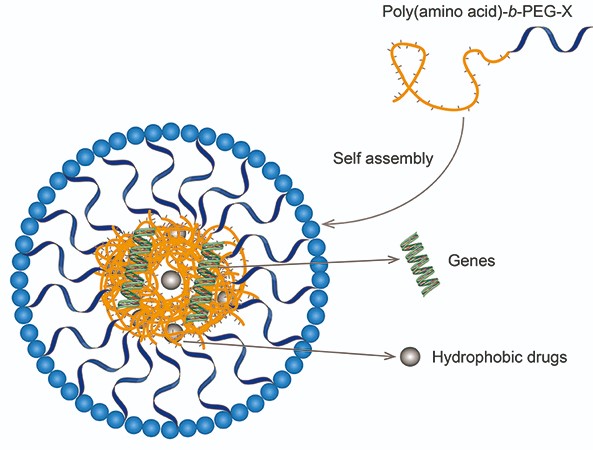

Block Copolymer Micelles

Block copolymer micelles (BCMs) emerge as potential nanocarriers in drug delivery because they self-assemble from amphiphilic block copolymers in water-based solutions and feature core-shell structures. The hydrophobic core holds poorly soluble drugs such as antineoplastic agents which improves solubility and lowers systemic toxicity while the hydrophilic part maintains colloidal stability and extends circulation time. The micelles show high drug-loading capacity along with controlled release kinetics and adjustable physicochemical properties which depend on both copolymer composition and the methods used for preparation.

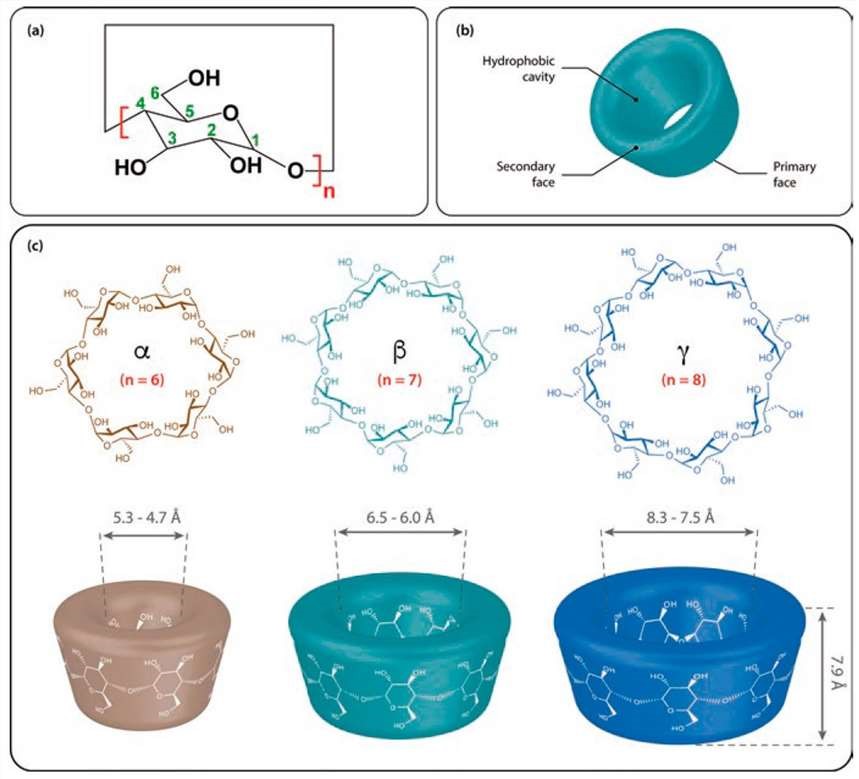

Cyclodextrin

Cyclodextrin (CD) consists of cyclic oligosaccharides sourced from amylose through the action of cyclodextrin glucosyltransferase which includes 6 to 12 D-pyranose units with the specific molecular forms of 6, 7 and 8 glucose units identified as α-, β-, and γ-cyclodextrin which now find extensive use in drug delivery systems. Van der Waals forces along with hydrophobic interactions between the inner cavity and outer shell of cyclodextrin enable its co-assembly with different small molecules.

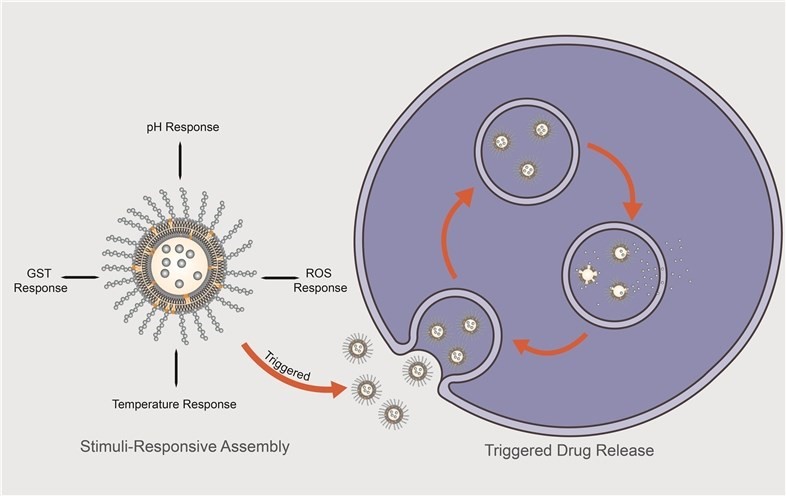

Enviromental Responsive Copolymers

Drug delivery research focuses on environmental responsive copolymers because they transform physicochemically when exposed to particular environmental signals. Scientists create copolymers which respond to environmental stimuli by changing their solubility, shape or charge when exposed to temperature shifts, pH changes or biological signals. These materials respond to environmental triggers which enables precise drug release while enhancing both the efficiency and safety of drug delivery systems.

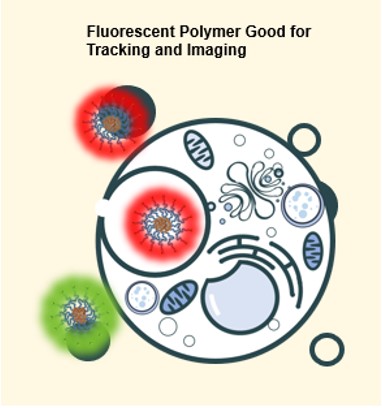

Fluorescent Polymers

Fluorescent polymers (FPs) serve as multifunctional materials in drug delivery systems that provide real-time monitoring of therapeutic agents through their natural or dye-added fluorescent properties. The ability of these structures to modify between hydrophilic and hydrophobic states leads to their self-assembly into micelles or nanoparticles that can carry hydrophobic drugs while enabling optical detection for biodistribution studies.

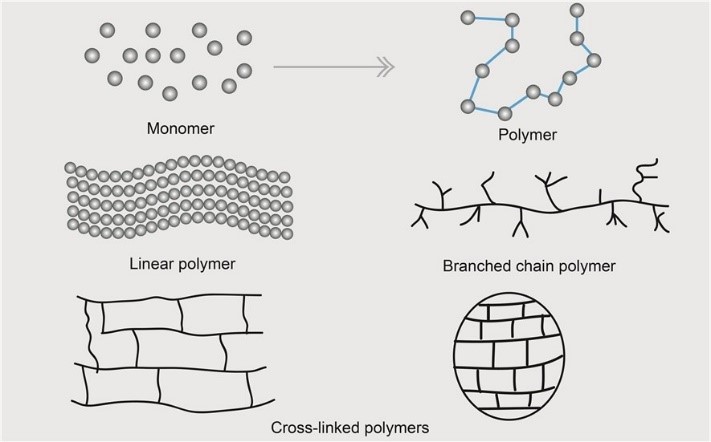

Monomers

Monomers which serve as polymer building blocks are becoming more important in drug delivery research because of their adaptable features and potential therapeutic use applications. These molecular units display distinctive features which allow them to serve as essential components in creating drug delivery systems that meet specific requirements.

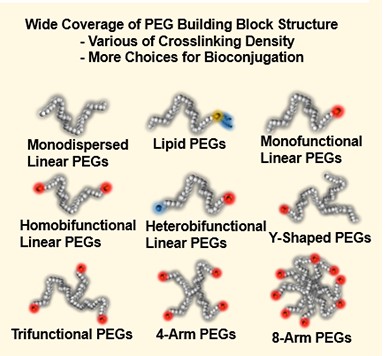

PEG Conjugations

By covalently connecting polyethylene glycol (PEG) to therapeutic molecules or nanocarriers, PEG conjugations increase drug delivery efficacy through better solubility and extended in-body circulation while lowering immune reactions. The hydrophilic "stealth" effect from these materials reduces immune detection and renal elimination. Tumor-targeting ligand connection and stimuli-responsive drug release become possible when using functionalized PEG derivatives like DSPE-PEG and FA-PEG. The use of these technologies includes protein drugs such as PEGylated interferons along with nanocarriers like liposomes and micelles and small-molecule conjugates which aim to maintain therapeutic effectiveness while lowering toxicity levels.

PEG Polyamino Acids

PEG Polyamino Acids (PPA) constitute a new class of biomaterials that have become a focal point for researchers studying drug delivery methods. The combination of polyethylene glycol (PEG) properties with the flexible nature of polyamino acids makes PPA an excellent foundation for constructing sophisticated drug delivery mechanisms.

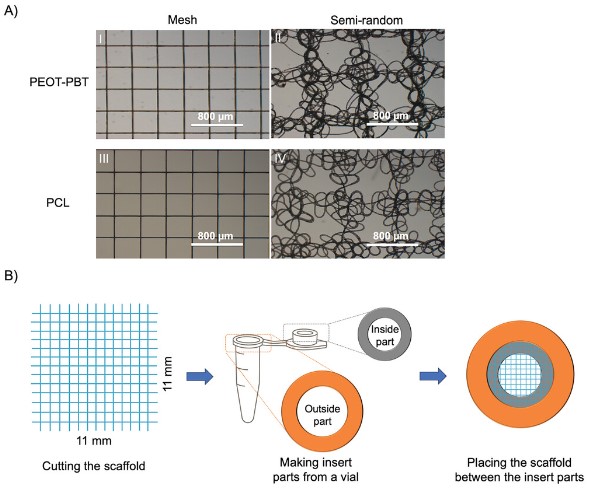

PEOT/PBT Multi-Block Copolymers

PEOT/PBT multi-block copolymers stand out as promising candidates in innovative drug delivery systems because they provide unique features that solve controlled release and bioavailability challenges. Poly(ethylene oxide terephthalate)/poly(butylene terephthalate) copolymers possess exceptional properties which make them highly suitable for effective drug delivery applications.

Poly(dimethylsiloxane)

Poly(dimethylsiloxane) serves as a common silicone polymer category under the PDMS designation. The structure of poly(dimethylsiloxane) remains colorless and odorless while it shows non-toxic characteristics and multiple advantages including superior chemical stability and outstanding thermal stability together with excellent lubrication and insulation capabilities. The unique features of PDMS make it a common choice for applications in medical, cosmetic, biomedical, soft material production (including silicone creation), microfluidic technologies and more. PDMS demonstrates excellent fluidity and easy shape processing together with high biocompatibility which leads to its widespread application in biomedical engineering.

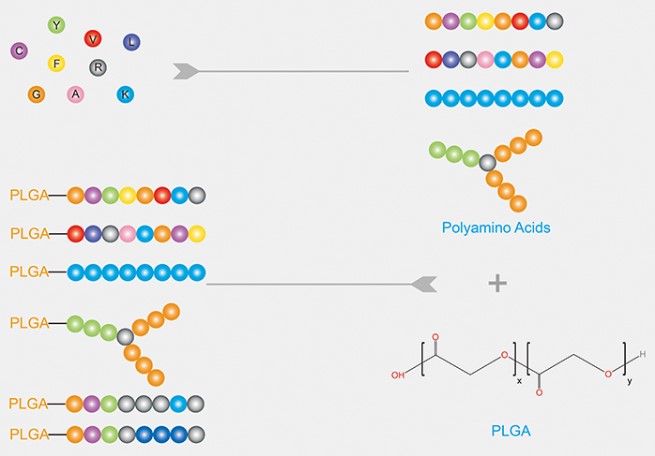

Polyamino Acids

Polyamino acids consist of amino acid monomers linked together through amide bonds. These compounds share similar chemical structures which makes them common materials in biomaterials research. People have the capacity to create numerous Polypeptide molecules with defined amino acid sequences and biological functions because amino acids exhibit extensive diversity and can arrange in tens of thousands of ways. Polyamino acids serve as natural polypeptide or protein mimetics which scientists produce through ring-opening polymerization of amino acid-N-carboxylic intracyclic anhydride.

Polyamino Acids-PLGA

Polyamino acids in conjunction with Poly(lactic-co-glycolic acid) (PLGA) represents the leading edge of drug delivery system advancements. When polyamino acids combine with PLGA they form a powerful system that merges their exclusive properties for advanced therapeutic uses. Polyamino acids demonstrate high biocompatibility and low immunogenicity which enhances the degradable properties of PLGA to create biomaterials suitable for specific drug release applications.

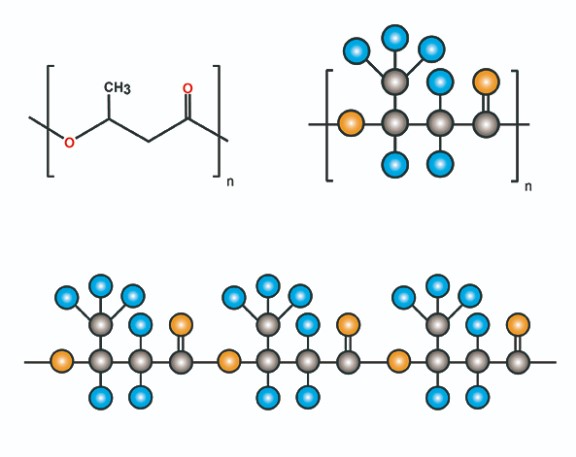

Polyhydroxybutyrate

Polyhydroxybutyrate (PHB) stands out as a potential solution for drug delivery systems because of its biodegradable nature along with biocompatibility and modifiable properties. PHB represents a naturally occurring polyester produced by different microorganisms which offers inherent benefits for pharmaceutical uses specifically in controlled therapeutic release.

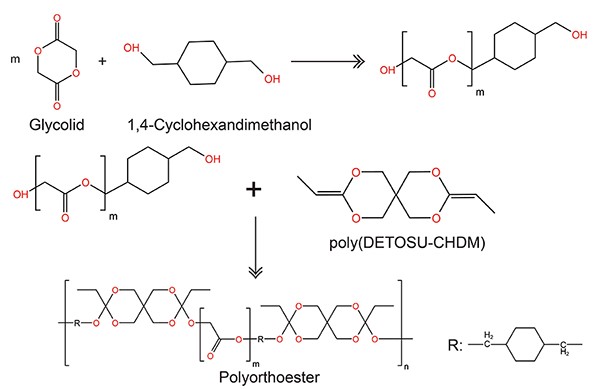

Polyorthoester

The drug delivery landscape recognizes polyorthoesters as a significant polymer group due to their unique features that enhance controlled release effectiveness. The defining feature of these polymers is their orthoester linkage structure which gives them beneficial properties for use in pharmaceutical formulations.

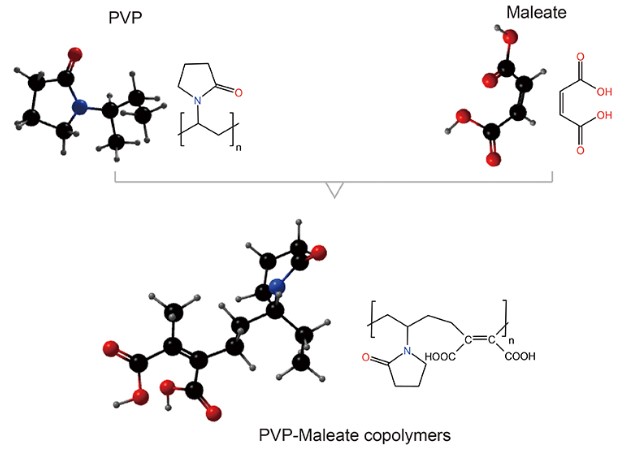

PVP-Maleate Copolymers

PVP-Maleate copolymers stand out as multifunctional materials for drug delivery because they present numerous features which tackle essential problems in pharmaceutical formulation development. The PVP-maleic acid copolymerization process creates a structure that merges the beneficial characteristics of both polyvinylpyrrolidone and maleic acid.

In the field of drug delivery, Biopolymers and Synthetic Polymers have become key materials for precision medicine drug delivery due to their natural properties and flexibility in artificial design. Biopolymers (such as chitosan and hyaluronic acid) can precisely target lesions and reduce immune rejection due to their natural biocompatibility and environmental responsiveness (such as pH or enzyme-triggered release). Synthetic polymers (such as PLGA and PEG) can regulate degradation rate and drug loading through chemical modification. For example, PLGA copolymers can customize the sustained release curve of anticancer drugs, while PEGylation can extend the drug's circulation time in the body. In addition to being used as drug delivery carriers alone, the combination of the two further breaks through limitations, such as chitosan-PEG composite carriers that have both targeting and long-term release, and biopolymer biomimetic interfaces that enhance the cellular uptake efficiency of nanoparticles. This collaborative innovation not only improves drug delivery efficiency, but also reduces toxic side effects, providing efficient and safe solutions for tumor treatment, gene delivery and tissue engineering.

Wide coverage of functional groups/targeting ligands/labels of polymers used for loading, modifications, specific targeting, tracking, and detecting

Various of density of the functional groups or different chemical geometries useful for fabricating biomaterials with controllable functionalities and other physical/chemical properties, such as mechanical properties for the crosslinkers

Improved biocompatibility, activity and, functionality performances of polymers

Enable drug-delivery cargos with controllable delivery profile

From non-GMP small laboratory scale, to commercial scale in GMP and non-GMP grade

Control formulations for many different types of drug encapsulated polymer formulations

Multi-modified/labeled nanomaterials for loading, specific targeting, tracking, and detecting

Biocompatible nanomaterials and bulk material fabrications

Biomedical applications as tissue engineering, pharmaceutical carriers, and medical devices

Antibacterial applications

Packaging materials with biobased films and containers in food industry

CD Bioparticles is a global supplier of "one-stop" custom polymer services to pharmaceutical, biotech and academic research institutions.

The primary distinction between biopolymers and synthetic polymers used in drug delivery systems lies in their origin and properties.

Biopolymers including chitosan and sodium alginate come from natural sources like plants and animals which makes them biodegradable and biocompatible with low immune response yet they suffer from weak mechanical strength and variable characteristics between batches.

Scientists can manipulate synthetic polymers (like PLA and PLGA) during chemical design to customize degradation rates and mechanical properties as well as drug release kinetics but they still present environmental threats because certain materials lead to non-degradable microplastic accumulation.

Key balance point: Biopolymers deliver high biocompatibility that benefits vaccine delivery applications whereas synthetic polymers enable precise control for complex systems in targeted cancer therapies.

Natural targeting mechanism: The adhesion of chitosan can enhance the efficiency of mucosal delivery, and sodium alginate forms a gel through pH response to achieve colon targeting.

Nanotechnology empowerment: Biopolymers (such as melanin extracted from black soldier flies) are made into nanoparticles to increase drug loading and the ability to penetrate the blood-brain barrier.

Challenges: Batch stability issues need to be addressed, and active targeting needs to be enhanced through surface modification (such as antibody coupling).

Stimulus-responsive design:

pH-sensitive (such as PLGA): release drugs in the slightly acidic environment of tumors.

Temperature-sensitive (such as PNIPAM): trigger drug release through local hyperthermia.

Photoresponsive: use near-infrared light to control the disintegration of nanocarriers to achieve precise release in time and space.

Clinical case: PLA-DX-PEG copolymer successfully delivers BMP-2 protein in bone regeneration, achieving controlled release and material integration.

Technical bottlenecks:

Long-term safety: the organ accumulation risk of degradation products (such as lactic acid of PLA) needs to be systematically evaluated.

Scaled production: the purification process of biopolymers and the precision synthesis of synthetic polymers are expensive.

Regulatory framework:

It is urgent to establish standardized test methods for biodegradability (such as ISO 14855).

It is necessary to clarify the clinical transformation standards of smart responsive materials (such as biosafety verification of optical/magnetic responsive systems).1. Download the template.

2. Enter product information on the template (maximum number of products: 200).

3. Load the file using selector below.

1. Download the template.

2. Enter product information on the template (maximum number of products: 200).

3. Load the file using selector below.