Virus-nanoparticle complexes refer to the attachment or growth of nanoparticles outside or inside the viral protein capsid. The complex has great application potential in the fields of drug delivery, gene therapy and material manufacturing. CD Bioparticles provides an integrated platform covering the development and manufacture of virus-nanoparticle conjugates from preclinical research to commercialization stage. We are committed to providing a wide range of services, including polymer synthesis, characterization, purification and isolation, bioconjugation, and side/end group modification.

It is well known that virus-like particles (VLPs) have become emerging tools in the field of nanomedicine due to their monodispersity, well-defined shape and size, and precise positioning for drug, targeting ligand, and polymer conjugation. Non-infectious VLPs have been applied in the fields of tumor targeting, drug delivery, immunotherapy and imaging, and the research on gene delivery has also received extensive attention. However, overcoming immune surveillance remains a challenge since VLPs activate innate and humoral immune responses. For example, studies using adeno-associated virus have shown that repeated injections may limit efficacy and may trigger an adverse inflammatory immune response. These effects can be mitigated by covalently coupling polymers to the capsid surface. In recent years, the method of attaching or growing synthetic polymers on or inside viral protein capsids has opened up completely new research ideas.

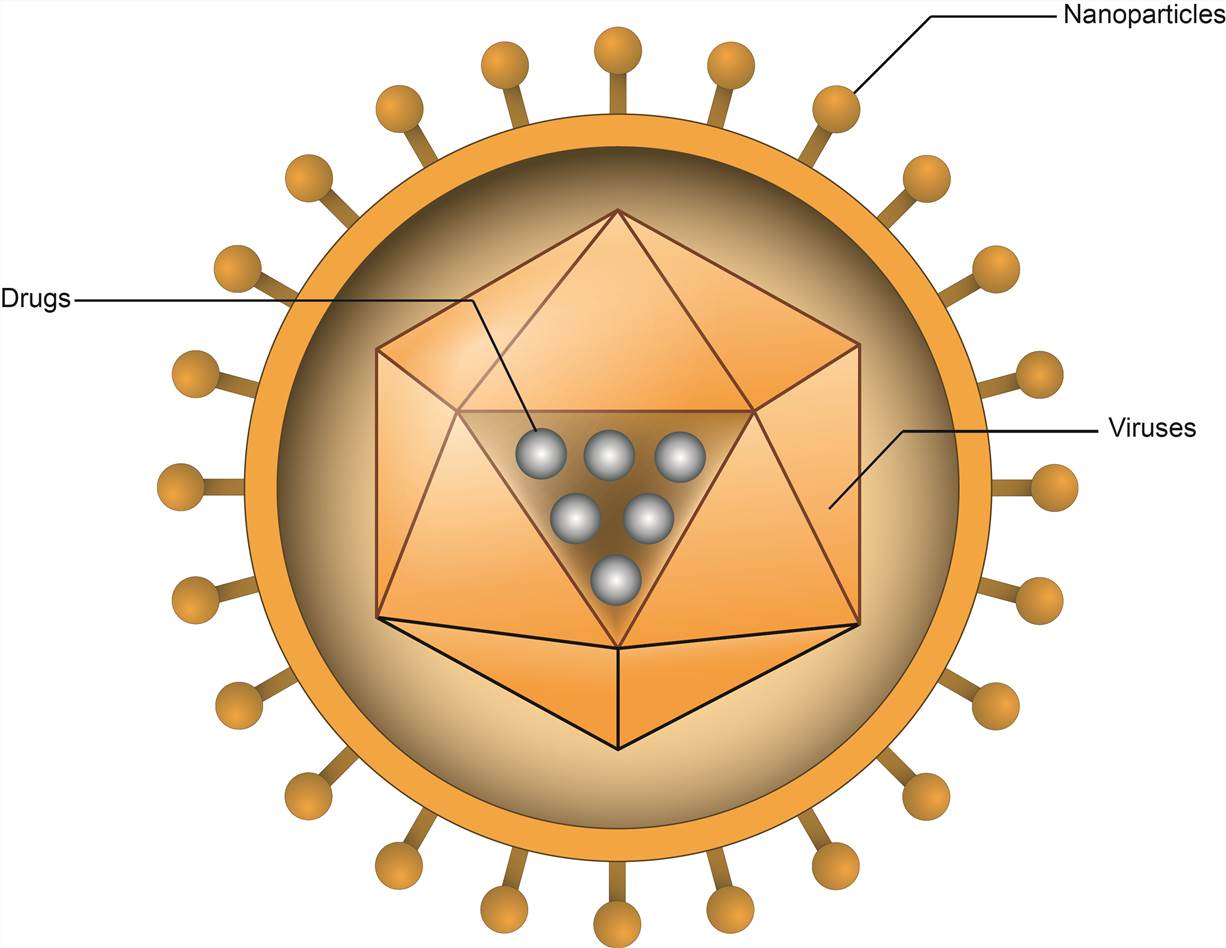

Figure 1. Viruses-Nanoparticles Conjugates.

Figure 1. Viruses-Nanoparticles Conjugates.

Virus-polymer conjugated materials have shown remarkable performances, which benefit from the unique properties of viruses and polymers, as well as the controllable and stable integration of functional molecules through covalent chemistry. In fact, researchers have found that by combining VLPs with polymers, their physical properties can be dramatically altered. The introduction of polymers can enhance the thermal stability of virus particles, especially has an important impact on the stability of secondary protein structures, and the application of cross-linking strategies further improves the stability of higher-order protein structures. In addition, another feature of virus-polymer composites is the controllable biological interaction. The advantage of using VLPs is that the position of active residues can be determined with atomic-level precision, allowing the spatial structure of substituents to be defined on the surface.

The surface grafting method is mainly applied to polymer attachment on the outer surface of VLPs, that is, attaching long polymer chains directly to the surface. Currently, the more common approach is to perform conjugation on surface-exposed lysine or tyrosine residues. With rich experience in polymer modification, CD Bioparticles' virus-polymer conjugation technology mainly supports customized services for bacteriophage Qβ, phage MS2 and tobacco mosaic virus (TMV). We provide our clients with a tailor-made approach to meet their needs.

To increase the yield of surface polymers and better control the polymerization process, a modification strategy of more densely loaded small-molecule initiators on the surface was employed. These initiators are then used in the subsequent polymerization step, which in principle leads to the formation of a controllable synthetic shell on the outer surface. Drawing on our expertise in polymer technology and PEG research, CD Bioparticles offers PEG glycosylation solutions for a variety of viruses to improve their pharmacokinetic and pharmacodynamic properties.

Viral capsids have been widely used in medicine because of their superior nanomaterial properties. They are inherently designed to safely house genomic material and allow stable transport in harsh environments. In addition, the unique monodisperse size and volume properties of viral capsids are also attractive. This precise volumetric feature allows the viral capsid to more precisely regulate the stoichiometry of potential catalytic reactions, as well as precisely control parameters such as drug dosage during drug delivery. More importantly, viral nanoparticles are biodegradable, which gives viral capsids a clear advantage over non-degradable materials. The protein capsid itself is well tolerated and, when properly functionalized, can achieve clinically useful circulating half-lives.

If you don't see what you need, or don't know what you need, please Contact Us and our team will work with you to find the right solution for your analysis.

Quotations and Ordering

Reference

1. Download the template.

2. Enter product information on the template (maximum number of products: 200).

3. Load the file using selector below.

1. Download the template.

2. Enter product information on the template (maximum number of products: 200).

3. Load the file using selector below.